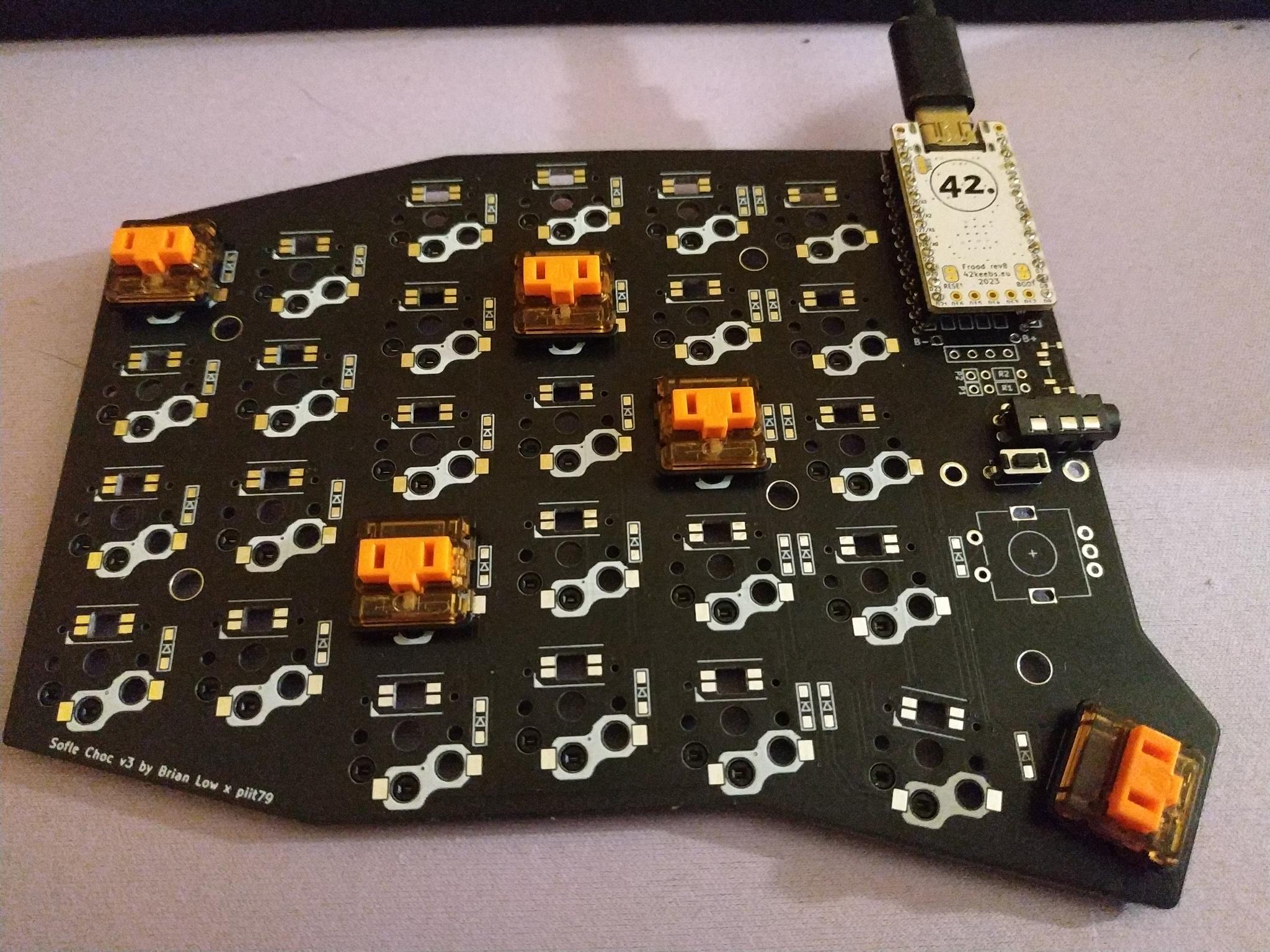

Hello, I have a question before starting the soldering process, can you confirm me the diode is correctly oriented ?

Thank you !

It should be but to be 100% sure you should check the schematic/PCB layout and the datasheet for the part. It’s extremely rare for a part like a diode to have a non-standard marking pattern so this would be correct, but it’s not unheard of.

Yes. You see that triangle with a line on top of it on the PCB? The line on your diode should be on the same side as the line on that marking.

Should be, that’s the orientation I solder mine and it works.

Thanks all for your comments and answers, I’ve just tests the keyboard and it seems to work pretty fine, I’m really happy, I didn’t expect to get something working directly!

As a reminder, here is the commands I’ve used to get the firmware to copy:

# Install the required compiler sudo apt install gcc-arm-none-eabi # Enter in the virtual environment . ~/.virtualenvs/qmk/bin/activate.fish # Check the keyboard qmk list-keyboards | grep sofle # Check the keymaps qmk list-keymaps -kb sofle_choc # Compile qmk flash -kb sofle_choc -km via -e CONVERT_TO=promicro_rp2040AFAIK orientation does not matter as long as it is consistent across the entire board. Double check with the PCB designer/manufacturer.

Edit: Why exactly am I being downvoted? What I said is correct. Hope it helps somebody as adding one line to the firmware is trivial, especially as compared to re-soldering.

While true, you would have to change the firmware to swap column and row polarity if you reverse all the diodes e.g.

in QMK. Conventionally, QMK assumes rows are on the cathode side of the diodes and drives the columns high.ROW2COLreverses that so that the rows are driven high and columns scanned instead.It’s best to stick to the convention so you avoid surprises.